Atomization technology is a fascinating and crucial part of modern science and industry. It plays a significant role in various applications, from fuel efficiency in transportation to medical treatments and food production. In this article, we will explore atomization in detail, including its mechanisms, techniques, benefits, and future trends. This extensive discussion will help readers appreciate the importance of atomization technology in everyday life and various industrial applications.

What Is Atomization?

Definition of Atomization

To start, let’s define atomization. Atomization is a process that transforms a liquid into tiny droplets or particles. When you spray water from a bottle, the mist created consists of countless tiny water droplets. Atomization works in a similar fashion, but it can be applied to various liquids, enabling a wide range of applications.

The Importance of Atomization

Understanding atomization is crucial because it impacts many aspects of our daily lives. From the fuel we use to the medicines we take, atomization technology underpins many industries. By breaking liquids into fine droplets, we can enhance efficiency, effectiveness, and safety in several applications.

Understanding the Mechanisms of Atomization Technology

The Physics of Atomization

Atomization involves complex physical principles, including fluid dynamics and thermodynamics. The transition of a liquid to a droplet phase can be influenced by factors like pressure, temperature, and the design of atomization systems.

Fluid Dynamics in Atomization Processes

Fluid dynamics plays a key role in understanding how liquids behave when atomized. The movement of liquid through nozzles, the impact of air resistance, and the interaction between droplets are all influenced by fluid dynamics. Understanding these principles is vital for optimizing atomization systems and ensuring consistent performance.

Particle Size Distribution in Atomization Technology

One important aspect of atomization is particle size distribution. The size of the droplets created during atomization affects their behavior and effectiveness in various applications. For instance, smaller droplets may evaporate faster, making them suitable for applications like fuel combustion or aerosol generation. In contrast, larger droplets may be more appropriate for coating surfaces or delivering medications. You Can Also Read This Understanding the Lacie 5big Network 2 6TB: A Comprehensive Guide

Comparative Analysis of Atomization Technology Techniques

Atomization can be achieved through several techniques, each with its own advantages and disadvantages. Understanding these methods allows us to choose the most appropriate one for a given application.

1. Spraying

Spraying is one of the most common methods of atomization. It involves pushing a liquid through a nozzle to create fine droplets. This technique is widely used in applications ranging from agricultural spraying to industrial coating processes.

Advantages of Spraying

- Versatility: Spraying can be adapted for various liquids, making it suitable for different industries.

- Control: It allows for precise control over droplet size and distribution.

2. Ultrasonic Atomization

Ultrasonic atomization employs high-frequency sound waves to create droplets. This technique is often used in medical devices, such as nebulizers, to deliver medication effectively.

Advantages of Ultrasonic Atomization

- Fine Droplet Size: Ultrasonic atomization produces very small droplets, ideal for inhalation therapies.

- Efficiency: It minimizes waste by ensuring that more of the liquid is effectively atomized.

3. High-Pressure Atomization

In high-pressure atomization, liquids are forced through a small nozzle at high pressure, resulting in the formation of fine droplets. This method is commonly used in automotive fuel injection systems.

Advantages of High-Pressure Atomization

- Improved Combustion: By atomizing fuel more effectively, combustion becomes more complete and efficient.

- Reduced Emissions: Better atomization leads to lower emissions in vehicles.

Comparative Effectiveness of Different Atomization Methods

While all three methods are effective, their suitability varies depending on the application. For example, ultrasonic atomization is ideal for pharmaceuticals, while high-pressure atomization is better for fuel injection systems. Choosing the right method involves considering factors such as droplet size, required efficiency, and specific application needs.

Benefits of Atomization Technology in Industrial Applications

Atomization technology has numerous benefits across various industrial applications. Let’s explore some of the key areas where atomization is particularly impactful.

1. Improving Fuel Efficiency

Atomization technology significantly improves fuel efficiency in transportation. By mixing fuel with air more effectively, atomization ensures more complete combustion. This is particularly important in the automotive and aerospace industries, where efficiency can lead to substantial cost savings and reduced environmental impact.

Innovations in Atomization Technology for Energy Efficiency

Recent innovations have focused on refining atomization techniques to maximize fuel efficiency. Advanced fuel injectors use high-pressure atomization methods to create finer fuel droplets, enhancing the combustion process and reducing fuel consumption.

2. Applications of Atomization Technology in Pharmaceutical Manufacturing

In the pharmaceutical industry, atomization is used to deliver medications effectively. Devices like nebulizers atomize liquid medications into fine mists, allowing for quicker absorption in patients with respiratory conditions. This approach improves the efficacy of treatments for conditions such as asthma and chronic obstructive pulmonary disease (COPD).

3. Atomization Technology in Food and Beverage Production

Atomization technology is also utilized in the food industry. For example, it allows for the production of powdered forms of liquids, such as milk powder. This process makes storage and transportation easier and can extend shelf life.

4. Enhancing Agricultural Practices

Farmers use atomization technology to apply fertilizers and pesticides to crops more efficiently. Atomizing these substances allows for better coverage with less waste, which can lead to improved crop yields and healthier plants.

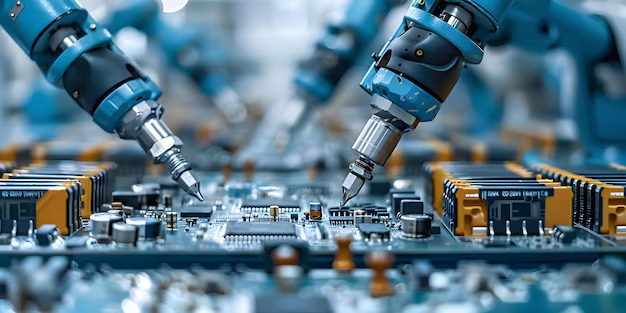

5. Advancing Spray Coating Processes

In industrial applications, atomization technology enhances spray coating processes. By atomizing paint or other coating materials, manufacturers can achieve smoother finishes and minimize waste. This is particularly important in industries such as automotive manufacturing and furniture production.

How Atomization Technology Enhances Spray Coating Processes

The application of atomization in spray coating involves the precise control of droplet size and distribution, leading to a uniform coating layer. This ensures that surfaces are coated evenly, reducing the likelihood of imperfections and improving the overall quality of the finished product.

Innovations in Atomization Technology for Environmental Sustainability

Atomization technology also plays a crucial role in promoting environmental sustainability. By optimizing processes and reducing waste, atomization can help industries become more eco-friendly.

1. Atomization Technology for Environmental Protection

Atomization technology is being explored for applications in environmental cleanup. For instance, researchers are investigating the use of atomized sprays to tackle oil spills or to control air pollution by atomizing neutralizing agents.

2. Future Trends in Atomization Technology for Manufacturing

As technology advances, we can expect to see more innovative applications of atomization in manufacturing. Researchers are exploring ways to optimize atomization systems for various applications, such as aerosol generation and additive manufacturing. This could lead to further improvements in efficiency and sustainability.

3. The Role of Temperature in Atomization Technology

Temperature significantly affects atomization processes. For example, higher temperatures can reduce the viscosity of liquids, making them easier to atomize. Understanding the role of temperature in atomization can help optimize processes for specific applications, improving overall efficiency.

Atomization Technology vs. Traditional Spraying Methods

When comparing atomization technology to traditional spraying methods, several key differences emerge. While traditional spraying methods may suffice for some applications, atomization offers enhanced precision and efficiency.

1. Precision and Control

Atomization technology allows for better control over droplet size and distribution compared to traditional methods. This precision is critical in applications where uniformity is essential, such as in medical treatments and spray coatings.

2. Efficiency and Waste Reduction

Atomization reduces waste by ensuring that more of the liquid is effectively used. Traditional spraying methods often result in overspray and uneven coverage, leading to increased material consumption.

3. Versatility Across Applications

Atomization technology can be adapted for various liquids and applications, making it more versatile than many traditional methods. Whether in pharmaceuticals, agriculture, or manufacturing, atomization provides tailored solutions to meet specific needs.

Recent Advancements in High-Pressure Atomization Technology

High-pressure atomization has seen significant advancements in recent years. Researchers and engineers have developed new nozzle designs and materials that enhance atomization efficiency. These advancements have led to improved fuel injection systems and reduced emissions in vehicles.

1. Impact of Nozzle Design on Atomization Efficiency

Nozzle design plays a critical role in the efficiency of atomization. Innovations in nozzle technology have led to better control over droplet size and distribution, resulting in improved performance across various applications.

2. Optimization Strategies for Atomization Systems

To maximize the benefits of atomization technology, industries are implementing optimization strategies. This includes fine-tuning parameters such as pressure, temperature, and nozzle design to achieve the desired droplet characteristics.

Atomization in Additive Manufacturing Applications

Atomization technology is increasingly being integrated into additive manufacturing processes. By atomizing materials, manufacturers can create finer layers and improve the overall quality of 3D-printed components. This innovation enhances the precision and performance of additive manufacturing, making it suitable for more complex applications. Visit the home page of Tech Impact Daily.

Conclusion

Atomization technology is more important than many people realize. It impacts various aspects of our daily lives, from the fuel we use to the medicines we take and the food we eat. By understanding atomization and its benefits, we can appreciate how it helps make our world better.

As we move forward, the future trends in atomization technology for manufacturing and other industries promise even more exciting developments. With a focus on optimization strategies, innovations in nozzle design, and a commitment to environmental sustainability, atomization technology will continue to play a crucial role in enhancing efficiency and effectiveness across multiple applications.

Whether in our cars, homes, or industries, atomization remains a key player in improving performance and sustainability. By embracing these advancements, we can look forward to a more efficient and eco-friendly future, driven by the remarkable potential of atomization technology.