In today’s fast-paced manufacturing world, finding the right Injection Molding manufacturer is crucial for businesses aiming to create high-quality plastic components. This process, integral to a myriad of industries, delivers precision, efficiency, and scalability. Whether you are a startup looking to prototype products or an established brand seeking large-scale production, selecting the ideal partner can make or break your operations.

Understanding Injection Molding and Its Applications

Injection molding is a manufacturing process that involves injecting molten materials into a mold to form specific shapes. The versatility of this method makes it a favorite in industries like automotive, consumer goods, healthcare, and electronics. A trusted Injection Molding manufacturer employs advanced technology and expertise to produce durable, lightweight, and cost-effective products.

Applications include creating car dashboards, medical devices, electronic housings, and everyday items like bottle caps. The adaptability of injection molding means products can be customized to meet specific requirements, which is why partnering with a reliable Injection Molding manufacturer is essential.

The Role of Technology in Modern Injection Molding

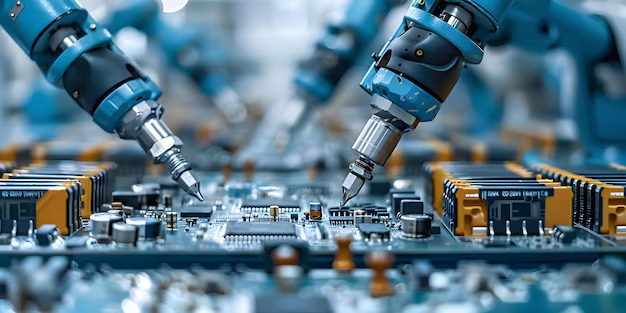

The technological advancements in the injection molding industry have transformed production capabilities. Today, leading Injection Molding manufacturers integrate automated systems, precision robotics, and advanced software to enhance efficiency and quality.

For example, CAD and CAM software allow for the design and testing of molds before production begins, ensuring minimal errors. Additionally, modern machinery supports the use of various materials, including thermoplastics, thermosets, and biodegradable polymers, which are in high demand for sustainable manufacturing.

When evaluating an Injection Molding manufacturer, look for facilities that invest in cutting-edge technology. This ensures superior product quality, reduced production time, and environmental compliance.

Benefits of Partnering with a Reputable Injection Molding Manufacturer

Collaborating with a trusted Injection Molding manufacturer offers numerous advantages. First and foremost, these manufacturers provide end-to-end solutions, from concept design to final production. Their expertise ensures that every product meets industry standards and client specifications.

Moreover, experienced manufacturers help reduce overall costs by streamlining the production process, optimizing material usage, and minimizing waste. Their ability to scale production quickly also allows businesses to meet market demands efficiently, an essential factor in today’s competitive environment.

Factors to Consider When Choosing an Injection Molding Manufacturer

Selecting the right Injection Molding manufacturer requires careful evaluation. Begin by assessing their experience and reputation within your industry. Manufacturers with a proven track record are more likely to understand your specific requirements.

Next, inspect their production facilities and equipment. Modern, well-maintained machinery is a hallmark of a reliable manufacturer. Additionally, inquire about their material expertise and ability to handle specialized polymers. If sustainability is a priority, ensure they offer eco-friendly solutions.

Customer service is another crucial factor. A good Injection Molding manufacturer maintains clear communication throughout the project, providing updates and addressing concerns promptly.

Case Studies: Success Stories in Injection Molding

Several businesses have thrived by partnering with a skilled Injection Molding manufacturer. For instance, a medical device company required precise, sterile components for their products. By collaborating with a manufacturer specializing in medical-grade plastics, they achieved their goals without compromising on quality.

Similarly, an electronics company needed durable, heat-resistant casings for their devices. With the support of an experienced Injection Molding manufacturer, they developed innovative solutions that outperformed competitors.

Such examples highlight the transformative impact of choosing the right partner.

Sustainability in Injection Molding

In an era of environmental awareness, many Injection Molding manufacturers are adopting sustainable practices. These include using recycled materials, minimizing energy consumption, and implementing waste management systems.

Sustainable injection molding not only benefits the planet but also enhances a company’s brand image. Consumers and businesses increasingly prefer environmentally friendly products, making sustainability a competitive advantage.

When evaluating a potential Injection Molding manufacturer, consider their commitment to green practices. Manufacturers investing in sustainability often stay ahead of regulatory requirements and market trends.

Future Trends in Injection Molding

The injection molding industry is continuously evolving. Innovations like 3D printing hybrid molding, AI-driven quality control, and Industry 4.0 integration are reshaping the landscape. These advancements allow Injection Molding manufacturers to deliver unparalleled precision and efficiency.

Another significant trend is the rise of personalized manufacturing. As demand for customized products grows, manufacturers are leveraging flexible systems to cater to niche markets.

By partnering with a forward-thinking Injection Molding manufacturer, businesses can stay competitive and capitalize on emerging opportunities.

Conclusion

Choosing the right Injection Molding manufacturer is a critical step for businesses aiming to produce high-quality, cost-effective products. By prioritizing technology, sustainability, and industry expertise, you can ensure successful partnerships and achieve long-term success.

As the industry continues to innovate, partnering with a reliable manufacturer will empower you to meet market demands, enhance product quality, and stay ahead in a competitive global economy. Whether you’re seeking large-scale production or custom solutions, the right Injection Molding manufacturer will be instrumental in driving your business forward.