Palletizing technology plays a critical role in the logistics and supply chain industry. It is the process of stacking products onto pallets for easier transportation and storage. Pallets serve as a sturdy base for goods, allowing them to be moved efficiently with forklifts or pallet jacks. This process is essential for warehouses, factories, and distribution centers.

In recent years, there have been remarkable trends in palletizing technology that are reshaping the landscape of how products are stacked and transported. These trends include increased automation, the use of robotics, smart solutions, and sustainable practices. Understanding these advancements can help businesses enhance their operations and improve overall efficiency. This article will delve into various trends and innovations in palletizing technology, exploring their benefits and implications for the industry.

1. Automation in Palletizing

Automation is perhaps the most significant trend in palletizing technology. Businesses are increasingly turning to automated systems to streamline their palletizing processes. Automated palletizers are machines that can automatically stack products onto pallets without the need for human intervention.

The Rise of Automated Systems

Automated palletizers can handle a wide variety of products, from bags and boxes to irregularly shaped items. They are designed to increase efficiency and reduce labor costs. By automating the palletizing process, companies can minimize human error and enhance productivity.

Key Benefits of Automation:

- Speed: Automated systems can palletize products much faster than manual processes. This increased speed is essential in high-demand environments where time is crucial.

- Consistency: Machines provide consistent stacking patterns, ensuring that products are securely placed on pallets. This consistency minimizes damage during transportation.

- Cost Efficiency: While the initial investment in automation may be high, the long-term savings in labor costs and increased efficiency often outweigh the expenses.

Types of Automated Palletizers

There are several types of automated palletizers, each designed for specific applications:

- Robotic Palletizers: These systems use robotic arms to pick and place products on pallets. They are highly flexible and can be programmed to handle different product sizes and shapes.

- Conventional Palletizers: These machines typically use a series of belts and conveyors to move products into position for stacking. They are ideal for high-volume operations and can handle large quantities of items quickly.

- Hybrid Systems: Combining elements of both robotic and conventional palletizers, hybrid systems offer versatility and efficiency, making them suitable for various production environments.

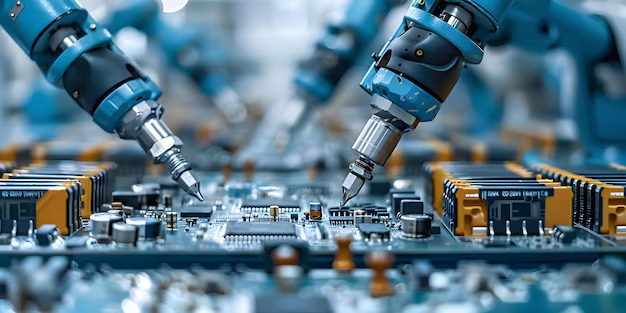

2. Robotics in Palletizing

Robotics has revolutionized many industries, and palletizing is no exception. The use of robots in palletizing systems enhances flexibility and precision. Robotic palletizers can quickly adapt to different product sizes and shapes, making them an ideal choice for diverse production lines.

The Advantages of Robotic Palletizing

Robotic palletizers offer several advantages that traditional methods cannot match:

- Flexibility: Robots can easily switch between different tasks and products. This adaptability allows businesses to respond quickly to changing market demands.

- High Precision: Robotic arms are equipped with advanced sensors and cameras, enabling them to pick and place products with high accuracy. This precision reduces product damage and ensures optimal pallet configurations.

- Space Efficiency: Robots occupy less floor space compared to conventional palletizing systems. This compact design allows for more efficient use of warehouse space.

Innovations in Robotic Technology

Recent advancements in robotic technology have further enhanced their capabilities in palletizing:

- Artificial Intelligence (AI): AI-powered robots can learn from their environment and improve their performance over time. They can analyze patterns and optimize their movements for better efficiency.

- Machine Learning: Machine learning algorithms enable robots to adapt to different product characteristics and adjust their operations accordingly. This capability is particularly beneficial in environments with varied product lines.

- Collaborative Robots (Cobots): Cobots are designed to work alongside human operators. They can assist with palletizing tasks without replacing human workers, enhancing overall productivity and safety.

3. Smart Palletizing Solutions

The introduction of smart technology is another significant trend in palletizing. Smart palletizers leverage sensors, cameras, and data analytics to improve efficiency and accuracy. These systems can collect real-time data on palletizing operations and analyze it to identify inefficiencies.

Benefits of Smart Solutions

- Data-Driven Decisions: Smart palletizing systems provide valuable insights into operational performance. Businesses can use this data to make informed decisions and optimize their palletizing processes.

- Improved Productivity: By analyzing data and identifying bottlenecks, smart solutions help businesses streamline their operations and enhance productivity.

- Predictive Maintenance: Smart palletizers can monitor their performance and predict maintenance needs. This proactive approach reduces downtime and minimizes disruptions to production.

How Smart Technology Works

Smart palletizing solutions use a combination of hardware and software components to function effectively:

- Sensors: Sensors monitor product dimensions, weights, and shapes. They ensure that products are stacked correctly and securely.

- Cameras: High-resolution cameras capture images of the palletizing process. This visual data helps in quality control and ensures that products are placed accurately.

- Software Analytics: Advanced software analyzes data collected from sensors and cameras. It generates reports and provides recommendations for improving palletizing operations.

4. Sustainable Palletizing Practices

Sustainability is a growing concern in many industries, including palletizing. As businesses strive to reduce their environmental impact, sustainable palletizing practices are becoming more prevalent. This trend involves using eco-friendly materials and processes to minimize waste and conserve resources. You Can Also Read This Verdant Technologies and Gulftech: Innovations for a Greener Future

Eco-Friendly Materials

Many companies are exploring sustainable alternatives to traditional pallet materials. Some eco-friendly options include:

- Recyclable Pallets: Pallets made from recyclable materials can be reused or repurposed, reducing waste in landfills.

- Biodegradable Pallets: Some companies are developing pallets made from biodegradable materials, ensuring that they break down naturally over time.

- Wood Alternatives: Materials like plastic or composite materials offer a sustainable alternative to wood pallets. These alternatives are often more durable and resistant to moisture and pests.

The Importance of Sustainability

Adopting sustainable palletizing practices benefits both businesses and the environment:

- Reducing Carbon Footprint: By using eco-friendly materials and processes, companies can significantly lower their carbon emissions and contribute to environmental conservation.

- Meeting Consumer Demands: As consumers become more environmentally conscious, they prefer to purchase from companies that prioritize sustainability.

- Regulatory Compliance: Governments are increasingly implementing regulations to promote sustainability. Businesses that adopt eco-friendly practices are better positioned to comply with these regulations.

5. Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside human operators. Unlike traditional industrial robots, cobots are equipped with safety features that allow them to operate in close proximity to workers. This collaborative approach enhances overall efficiency in palletizing operations.

Benefits of Cobots in Palletizing

- Easy Integration: Cobots can be easily integrated into existing workflows. They do not require extensive modifications to the production line, making them a cost-effective solution for many businesses.

- Enhanced Safety: Cobots are designed to work safely alongside humans. They are equipped with sensors that detect human presence and can adjust their movements accordingly.

- Increased Productivity: By assisting human workers with repetitive tasks, cobots allow employees to focus on more complex activities, leading to increased overall productivity.

Applications of Cobots in Palletizing

Cobots are versatile and can be used in various palletizing applications:

- Case Packing: Cobots can assist with packing products into cases before palletizing. This integration streamlines the entire packaging process.

- Sorting and Stacking: Cobots can sort products and stack them on pallets, ensuring efficient organization and use of space.

- Quality Control: Cobots can be programmed to perform quality checks on products before they are palletized, ensuring that only high-quality items are shipped.

6. Advanced Vision Systems

Advanced vision systems are becoming essential in modern palletizing technology. These systems use cameras and sensors to identify products and ensure accurate placement on pallets. By incorporating vision technology, businesses can significantly improve their palletizing accuracy and efficiency.

Features of Advanced Vision Systems

- High Resolution: High-resolution cameras provide detailed images of products, allowing for precise identification and positioning.

- Real-Time Processing: Vision systems can process images in real time, ensuring that products are palletized correctly without delays.

- Integration with AI: Integrating vision systems with AI technology enhances their capabilities. AI algorithms can analyze images and provide insights for optimizing palletizing processes.

The Role of Vision Systems in Quality Control

Vision systems play a crucial role in quality control during palletizing:

- Defect Detection: Vision systems can identify defective products before they are palletized, preventing damaged items from reaching customers.

- Packing Verification: These systems ensure that the correct products are packed and palletized according to specifications.

- Dimensional Inspection: Vision systems can measure product dimensions to ensure they meet quality standards.

7. Flexible Palletizing Solutions

Flexibility is vital in today’s fast-paced market. Companies are increasingly seeking palletizing solutions that can adapt to changing needs. Flexible palletizers are designed to handle various products and packaging types without extensive reconfiguration.

Advantages of Flexible Palletizing

- Adaptability: Flexible palletizers can accommodate different product sizes and shapes. This adaptability allows businesses to respond quickly to changing market demands.

- Reduced Downtime: By minimizing the time needed for changeovers, flexible palletizing solutions reduce downtime and improve overall efficiency.

- Cost-Effectiveness: Flexible systems can handle multiple product lines, eliminating the need for separate palletizing solutions for each product.

Innovations in Flexible Palletizing Technology

Recent advancements in flexible palletizing technology include:

- Modular Design: Modular palletizing systems allow businesses to customize their setups based on specific needs. Companies can add or remove modules as required, enhancing flexibility.

- Easy Programming: Many flexible palletizers come with user-friendly interfaces that make programming changes quick and simple. Operators can adjust settings without extensive training.

- Integration with Other Systems: Flexible palletizers can easily integrate with existing production and packaging systems, ensuring seamless operations.

Conclusion

The trends in palletizing technology are transforming how products are stacked, stored, and transported. Automation, robotics, smart solutions, and sustainable practices are just a few of the advancements reshaping the industry. As businesses embrace these innovations, they can enhance efficiency, reduce costs, and meet the growing demands of the market.

Understanding these trends is essential for companies looking to remain competitive in today’s fast-paced environment. By investing in modern palletizing solutions, businesses can improve their operations and contribute to a more sustainable future.