Magnetostrictive sensor technology might sound complex, but it’s actually a fascinating and important field in modern technology. Imagine you have a special sensor that can measure things by changing its shape when exposed to a magnetic field. This is what magnetostrictive sensors do. They use a property called magnetostriction, where certain materials change shape slightly when exposed to a magnetic field. This tiny change can be measured very precisely, making these sensors incredibly useful for various applications.

How Magnetostrictive Sensors Work

To understand magnetostrictive sensors, let’s break it down into simple parts. Think of a magnetostrictive sensor as a tiny stick that gets a little longer or shorter when a magnet is near it. This stick is made of a special material that reacts to the magnetic field. The sensor measures how much the stick changes shape and uses that information to detect things like pressure, position, or force.

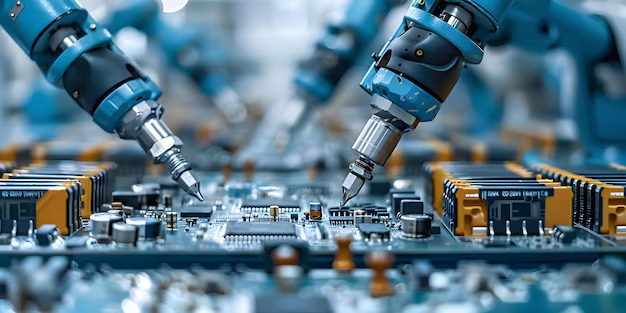

When a magnetic field is applied to the material inside the sensor, it causes the material to expand or contract. The sensor then converts this physical change into an electrical signal that can be read by machines or computers. This allows for highly accurate measurements and is useful in many different fields, including industrial automation, robotics, and aerospace.

The Role of Guided Waves in Magnetostrictive Sensors

Now, let’s talk about guided waves. Guided waves are like invisible ripples that travel through a material, just like waves on a pond. In magnetostrictive sensor technology, these guided waves are used to improve the sensor’s performance. They help the sensor measure things more accurately by providing additional information about how the material is changing shape.

Guided waves travel along the surface or through the material of the sensor, and they can be used to detect even tiny changes in the material. This is especially useful in applications where precision is crucial, such as in monitoring the health of structures like bridges or pipelines. By analyzing the guided waves, the sensor can detect problems like cracks or wear before they become serious.

Applications of Magnetostrictive Sensor Technology

Magnetostrictive sensor technology is used in many different areas. One common application is in industrial automation, where these sensors help machines work more efficiently. For example, they can measure the position of a robotic arm or the pressure of a hydraulic system.

In the aerospace industry, magnetostrictive sensors are used to monitor the health of aircraft. They can detect tiny changes in the structure of the aircraft, helping to prevent accidents and ensure safety. These sensors are also used in medical devices, such as ultrasound machines, where they help provide accurate measurements of the body’s internal structures.

Another important application is in structural health monitoring. Guided waves can be used to inspect bridges, dams, and pipelines for signs of damage or wear. This helps to prevent accidents and extend the lifespan of these critical structures.

Advantages of Magnetostrictive Sensors

Magnetostrictive sensors offer several advantages over other types of sensors. One major advantage is their high accuracy. Because these sensors measure changes in shape very precisely, they can provide detailed and reliable information.

Another advantage is their durability. Magnetostrictive sensors are often used in harsh environments where other sensors might fail. They can withstand extreme temperatures, pressures, and vibrations, making them suitable for a wide range of applications.

Additionally, magnetostrictive sensors are relatively easy to integrate into existing systems. They can be connected to various types of machinery and equipment without requiring major modifications. This makes them a versatile choice for many different industries.

Challenges and Limitations

Despite their many advantages, magnetostrictive sensors also have some challenges and limitations. One challenge is their cost. These sensors can be more expensive than other types of sensors, which might limit their use in certain applications.

Another limitation is their sensitivity to external factors. Magnetostrictive sensors can be affected by changes in temperature, magnetic fields, or other environmental conditions. This means that they need to be carefully calibrated and maintained to ensure accurate measurements.

Future Trends in Magnetostrictive Sensor Technology

Looking ahead, there are several exciting trends in magnetostrictive sensor technology. One trend is the development of smaller and more flexible sensors. Advances in materials and manufacturing techniques are making it possible to create sensors that are even more compact and adaptable to different applications.

Another trend is the integration of magnetostrictive sensors with other technologies, such as artificial intelligence and machine learning. This combination can enhance the sensor’s ability to analyze and interpret data, leading to more advanced and efficient systems.

Conclusion

Magnetostrictive sensor technology and guided waves represent an exciting area of innovation in the world of sensors. These technologies offer precise measurements and reliable performance across a range of applications. While there are challenges to overcome, the future looks bright for magnetostrictive sensors as they continue to evolve and improve.

By understanding how magnetostrictive sensors work and the role of guided waves, we can appreciate their impact on technology and the many ways they help us in our daily lives. Whether it’s ensuring the safety of our infrastructure or enhancing the performance of industrial machines, magnetostrictive sensors play a crucial role in modern technology.