Palletizing technology is changing fast, and it’s making a big difference in how businesses handle goods. From simple manual systems to advanced robotics, these changes are helping companies work faster and smarter. In this article, we’ll look at the most exciting trends in palletizing technology and how they’re shaping the future of warehouses and factories.

What is Palletizing Technology?

Palletizing technology encompasses the various automated systems and machinery used to stack and arrange products or materials onto pallets efficiently. This technology includes a range of solutions, such as robotic arms, conveyor systems, and gantry palletizers, which are designed to optimize the palletizing process. These systems utilize advanced sensors, software, and artificial intelligence to ensure precise placement of items, allowing for consistent stacking patterns that maximize space and stability. By automating palletization, businesses can significantly reduce labor costs, increase throughput, and enhance safety in the workplace. Additionally, palletizing technology plays a vital role in supply chain management by improving the speed and accuracy of product handling, ultimately leading to more efficient operations and better service delivery.

Why Are Palletizing Systems Important?

Palletizing systems are crucial in modern manufacturing and logistics for several reasons. First, they significantly enhance efficiency by automating the process of stacking and organizing products, which reduces the time and labor required for manual handling. This automation not only speeds up operations but also minimizes the risk of human error, leading to more accurate and consistent pallet configurations. Additionally, palletizing systems help optimize space utilization, allowing businesses to maximize storage capacity and streamline transportation logistics. They also improve workplace safety by reducing the physical strain on workers associated with manual lifting and stacking. Ultimately, the implementation of palletizing systems leads to cost savings, better inventory management, and improved overall productivity, making them essential for businesses aiming to stay competitive in today’s fast-paced market.

Palletizing systems are crucial for several reasons:

- Efficiency: They speed up the process of stacking and organizing goods.

- Safety: They reduce the risk of injuries by minimizing manual handling.

- Cost-Effective: Automated systems can lower labor costs and reduce errors.

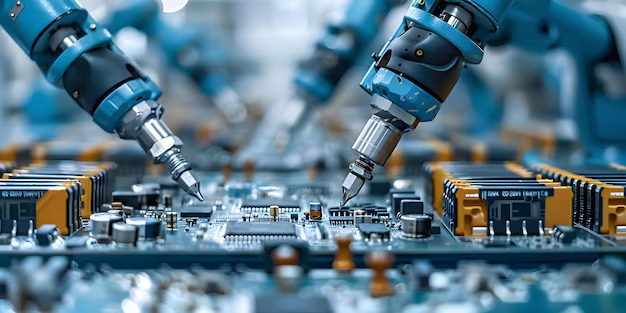

Trend 1: Robotics and Automation

Robotics and automation are at the forefront of advancements in palletizing technology, transforming how products are stacked and organized for storage and transportation. The integration of robotic arms and automated systems into palletizing processes allows for increased speed, precision, and consistency in handling various products. Robots can work around the clock, significantly reducing labor costs and minimizing human error in stacking and sorting tasks. These automated systems can easily adapt to different product shapes and sizes, making them ideal for diverse manufacturing environments. Additionally, advancements in artificial intelligence and machine learning enable robots to analyze data and improve their efficiency over time, optimizing pallet configurations for better stability and space utilization. This trend not only enhances operational efficiency but also contributes to workplace safety by reducing the physical strain on workers and minimizing the risk of accidents. As businesses strive for greater productivity and flexibility, the adoption of robotics and automation in palletizing systems is becoming increasingly essential. You Can Also Read This Technology Solutions Quant: Simplifying Complex Tech for Everyone

How Robotics Improve Palletizing

Robotic palletizers come with advanced features like:

- Flexibility: They can handle different sizes and types of products.

- Speed: They work faster than manual methods.

- Precision: They place products exactly where needed.

Trend 2: AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are making palletizing systems smarter. These technologies allow machines to learn from their environment and improve their performance over time.

Benefits of AI in Palletizing

- Predictive Maintenance: AI can predict when a machine needs repairs before it breaks down.

- Optimized Loading: AI can decide the best way to stack products to maximize space and minimize damage.

- Adaptability: AI systems can adjust to changes in product types and sizes without needing reprogramming.

Trend 3: Integration with Warehouse Management Systems (WMS)

Modern palletizing systems are being integrated with Warehouse Management Systems (WMS). This integration allows for real-time tracking and management of inventory.

How WMS Integration Helps

- Real-Time Data: Managers can see where products are at all times.

- Improved Accuracy: Reduces errors in inventory tracking.

- Efficient Operations: Streamlines the workflow from receiving to shipping.

Trend 4: Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside human workers. Unlike traditional robots that operate in isolation, cobots can interact safely with people, enhancing productivity.

Advantages of Cobots

- Safety: They are equipped with sensors to avoid collisions with humans.

- Ease of Use: They are user-friendly and easy to program.

- Cost-Efficiency: They are less expensive than traditional industrial robots.

Trend 5: Advanced Sensors and Vision Systems

Advanced sensors and vision systems are being integrated into palletizing machines to improve their capabilities. These systems help machines see and understand their environment better.

How Sensors and Vision Systems Work

- Quality Control: Sensors can detect defects or issues with products before they are palletized.

- Accuracy: Vision systems ensure that products are placed correctly on pallets.

- Adaptability: They allow machines to handle a variety of product types and sizes.

Trend 6: Sustainability and Eco-Friendly Solutions

Sustainability is becoming a key focus in palletizing technology. Companies are looking for ways to reduce their environmental impact by using eco-friendly materials and processes.

Sustainable Practices in Palletizing

- Recyclable Materials: Using pallets made from recycled or biodegradable materials.

- Energy Efficiency: Developing machines that use less energy.

- Waste Reduction: Implementing systems that minimize waste during the palletizing process.

Trend 7: Customized Solutions

As businesses grow and their needs change, there’s a growing trend towards customized palletizing solutions. These systems are tailored to meet specific requirements of different industries and products.

Benefits of Customized Palletizing Systems

Customized palletizing systems offer numerous benefits tailored to meet the specific needs of a business. One of the primary advantages is increased efficiency, as these systems can be designed to handle unique product sizes, shapes, and weights, optimizing the stacking process for maximum throughput. Customization also allows for flexibility in adapting to varying production volumes and changing market demands, ensuring that the system can grow with the business. Additionally, tailored palletizing solutions can enhance workplace safety by minimizing manual handling and reducing the risk of injuries associated with repetitive lifting tasks. These systems can also improve space utilization by creating specific stacking patterns that make the best use of pallet and storage space. Furthermore, customized palletizing systems can integrate seamlessly with existing production lines and inventory management software, resulting in smoother operations and better overall productivity. Ultimately, investing in a customized palletizing solution can lead to significant cost savings, improved operational efficiency, and a competitive edge in the market.

- Tailored Design: Systems designed to fit the unique needs of a business.

- Scalability: Easily adjusted as business needs change.

- Efficiency: Customized solutions can improve overall efficiency by addressing specific challenges.

Trend 8: Enhanced Safety Features

Safety continues to be a top priority in palletizing technology. New safety features are being added to protect workers and ensure smooth operations.

Key Safety Features

- Emergency Stop Buttons: Allowing immediate halting of machines in case of emergency.

- Safety Shields: Protecting workers from moving parts.

- Training Systems: Providing virtual training for workers to understand the safe operation of machines.

People also ask

What is a palletizing system?

A palletizing system is an automated process used to arrange products or materials onto a pallet in a structured and efficient manner, making them easier to store or transport. These systems, often incorporating palletizing technology examples like robotic arms, gantry palletizers, and automated guided vehicles (AGVs), are widely used in manufacturing and logistics industries to handle large volumes of goods quickly and accurately. By utilizing these advanced technologies, palletizing systems stack boxes, containers, or other items in specific patterns to maximize pallet space, reducing labor costs and ensuring safe handling during shipping. For further details on these technologies, you can explore resources like a palletizing technology PDF, which provides in-depth information on system designs and applications. Visit the home page of Tech Impact Daily.

What is the Palletization process?

The palletization process involves organizing and stacking products or materials onto pallets in a way that maximizes efficiency for storage and transportation. Palletization meaning refers to the systematic arrangement of goods, often in layers, to ensure secure and stable stacking. This process is crucial for streamlining logistics, as it allows goods to be easily handled by forklifts or automated systems. A palletizer machine is often used to automate the process, reducing manual labor while ensuring precise stacking for better stability and space utilization. The palletization process is widely used in industries such as manufacturing, retail, and warehousing to protect goods during transit and optimize operational efficiency.

What does palletizing mean?

Palletizing refers to the process of stacking and arranging products, materials, or packages onto pallets for easier handling, storage, and transportation. This process is essential in various industries, such as manufacturing, warehousing, and logistics, where large quantities of goods need to be organized efficiently. Palletizing can be done manually or through automated systems, such as a manual palletizer or an industrial palletizer, both designed to quickly and accurately place items in specific patterns on the pallet. The primary goal of palletizing is to maximize the use of pallet space, ensure the stability of stacked goods, and streamline the movement of products during shipping or storage.

What materials are used for palletizing?

Various materials are used for palletizing to ensure that products are securely stacked and protected during storage or transportation. The most common materials include wooden pallets, which are sturdy and widely used in many industries, and plastic pallets, known for their durability, lightweight nature, and resistance to moisture. For heavy-duty or industrial settings, metal pallets, typically made of steel or aluminum, are used. Automated systems like the gantry palletizer play a key role in stacking these materials efficiently. In addition to pallets, materials such as stretch film, shrink wrap, and strapping are used for securing the load during pallet handling. Protective padding or corner protectors may also be used to safeguard fragile or irregularly shaped items during the palletizing process.

Conclusion

Palletizing technology is evolving rapidly, with new trends and innovations making a significant impact on the industry. From robotics and AI to sustainability and customized solutions, these advancements are making palletizing more efficient, accurate, and environmentally friendly. As technology continues to advance, we can expect even more exciting developments in the future.

By staying informed about these trends, businesses can better prepare for changes and opportunities in palletizing technology, leading to improved efficiency and success.